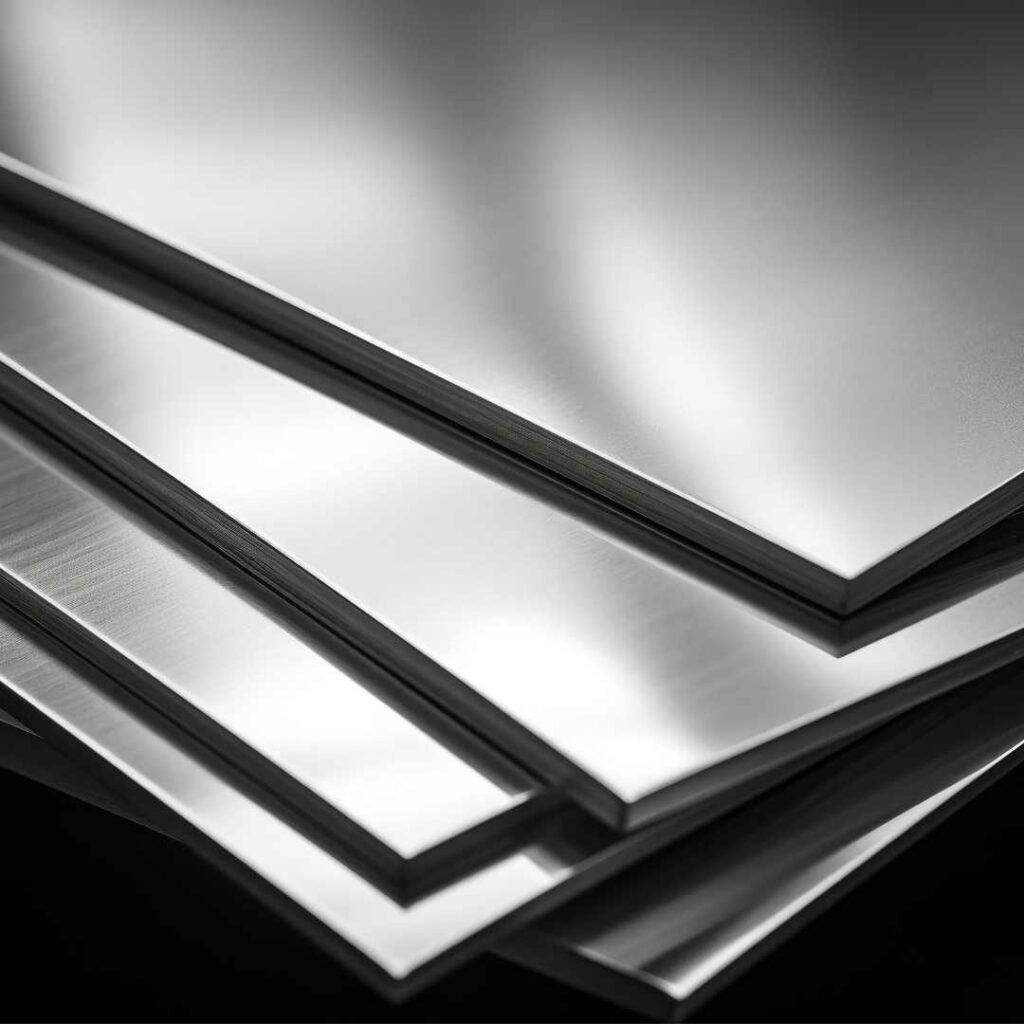

Explore HAFSA’s selection of hot rolled plates, a key steel material crafted through the hot rolling process. During this method, the steel plate undergoes heating before passing through rolling mills, culminating in the final product. Processed at elevated temperatures, hot-rolled steel plates undergo structural transformations, resulting in favourable mechanical and physical properties. Widely utilised across various industries, hot-rolled steel plates boast high hardness and ductility, distinguishing them as indispensable materials in industrial applications. With diverse applications, these plates play a pivotal role in enhancing industrial processes and outcomes.

At HFSA, we specialise in Hot Rolled Coils, a process known for its heat-intensive method of steel processing. During hot rolling, steel is subjected to temperatures above its re-crystallization point, allowing for easier shaping and forming of the material. After being rolled into coils, the steel is left to cool, albeit with slight shrinkage, resulting in products that are more malleable and easier to handle. While hot rolled steel may not be suited for precision applications due to its variability in size and shape, it excels where dimensional tolerances and surface finish are less critical. Our Hot Rolled Coils, including HSLA, Corten Steel, Structural, Commercial, and Pressure grades, serve as a versatile solution, bridging the gap between affordability and quality. At HFSA, we offer a comprehensive selection of HR Coils sourced from the finest mills worldwide, meeting various Indian and International Standards to accommodate diverse segment requirements.

TMT Rebars play a vital role in construction projects, providing essential tensile

strength to support the structure’s load. HFSA offers a range of rebars tailored to

various construction needs. For smaller structures, Fe 415 is commonly utilised, while

heavy-duty projects such as flyovers and high-rises benefit from Fe 500, renowned for

its exceptional strength. Fe 500 belongs to the Super Ductile rebars category, boasting

superior ductility and bond strength. Notably, these rebars possess the ability to absorb

significant energy during seismic events, making them particularly well-suited for

earthquake-prone regions. Our TMT Rebars adhere to a variety of Indian and

International Standards, ensuring they meet the diverse requirements of different

segments.

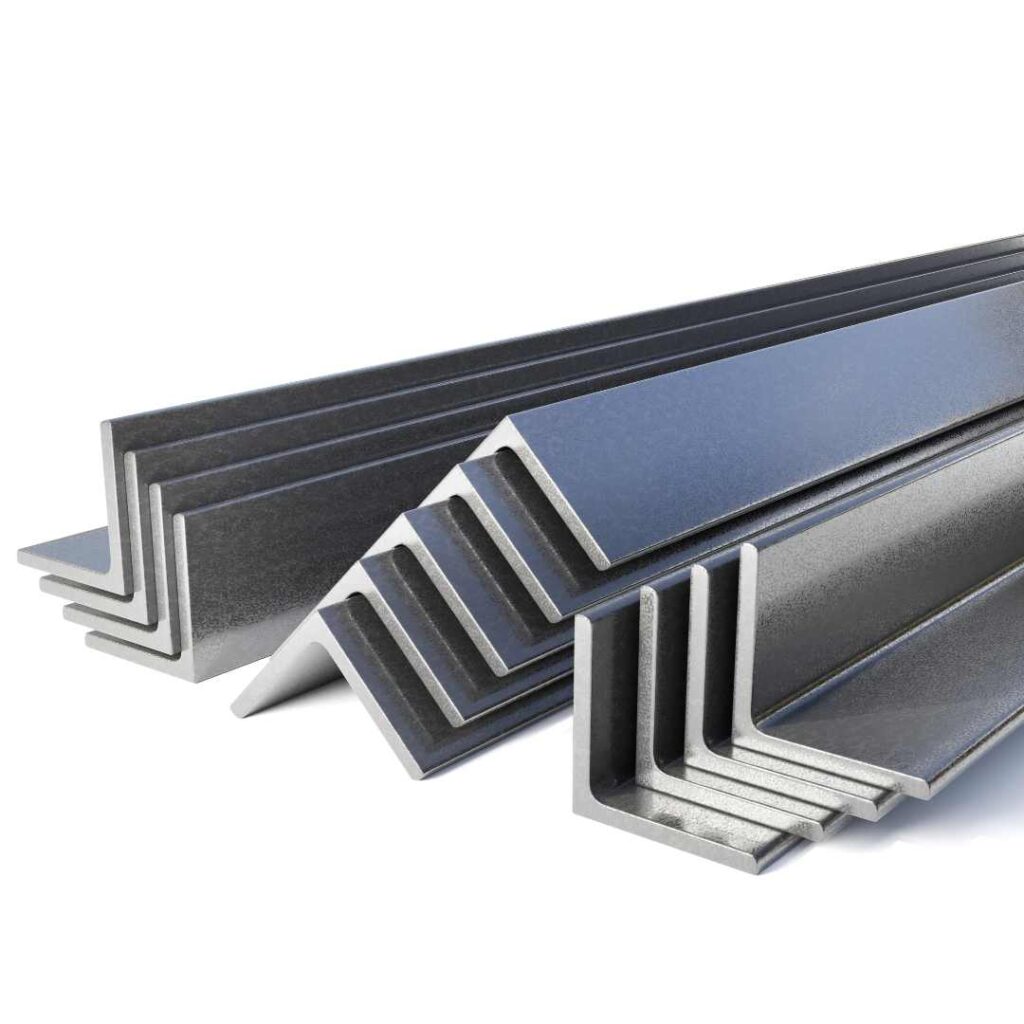

Structural Angles are versatile steel bars featuring an L-shaped cross-section with equal or unequal legs forming a sturdy 90-degree angle. Manufactured from hot-rolled carbon steel or high-strength low alloy steel, our Structural Angles offer exceptional stability, ideal for a multitude of structural applications, fabrication projects, and repairs. Available in various lengths and sizes, our steel angles adhere to stringent Indian and International Standards, ensuring superior quality and meeting diverse segment needs.

HFSA’s range of Structural Channels, commonly known as C-channels is expertly rolled

from steel sheets into either C or U shapes, featuring a wide web and two flanges. Whether parallel or tapered, these channels offer exceptional structural strength, ideal for diverse industrial applications such as machinery, enclosures, and vehicles. With a variety of thicknesses and sizes available, our Steel Channels adhere to stringent Indian and International Standards, ensuring they meet the diverse requirements of various segments.

Beams are essential structural components that establish a secure load path for transferring weight and forces from a structure to its foundations and into the ground. Beams, also referred to as I-Beams, H-Beams, or W-Beams, serve as horizontal structural elements, effectively bearing loads perpendicular to their longitudinal direction. They provide crucial support for floors, ceilings, and roofs while redistributing loads to the structure’s vertical load-bearing elements. Available in diverse configurations, our beams are carefully selected to match the specific load requirements of each application. Rest assured, our sections adhere to a range of Indian and

International Standards to fulfil the varied needs of different segments.

ERW (Electrical Resistance Welding) pipes are manufactured through the cold forming of steel

coils into a cylindrical shape. Initially, this process utilised low-frequency A.C. current to heat

the edges. However, since 1970, the process has transitioned to high-frequency A.C. current,

resulting in superior weld quality. Our ERW steel pipes come in diverse diameters, wall thicknesses, finishes, and grades, ensuring versatility and reliability for a multitude of applications.

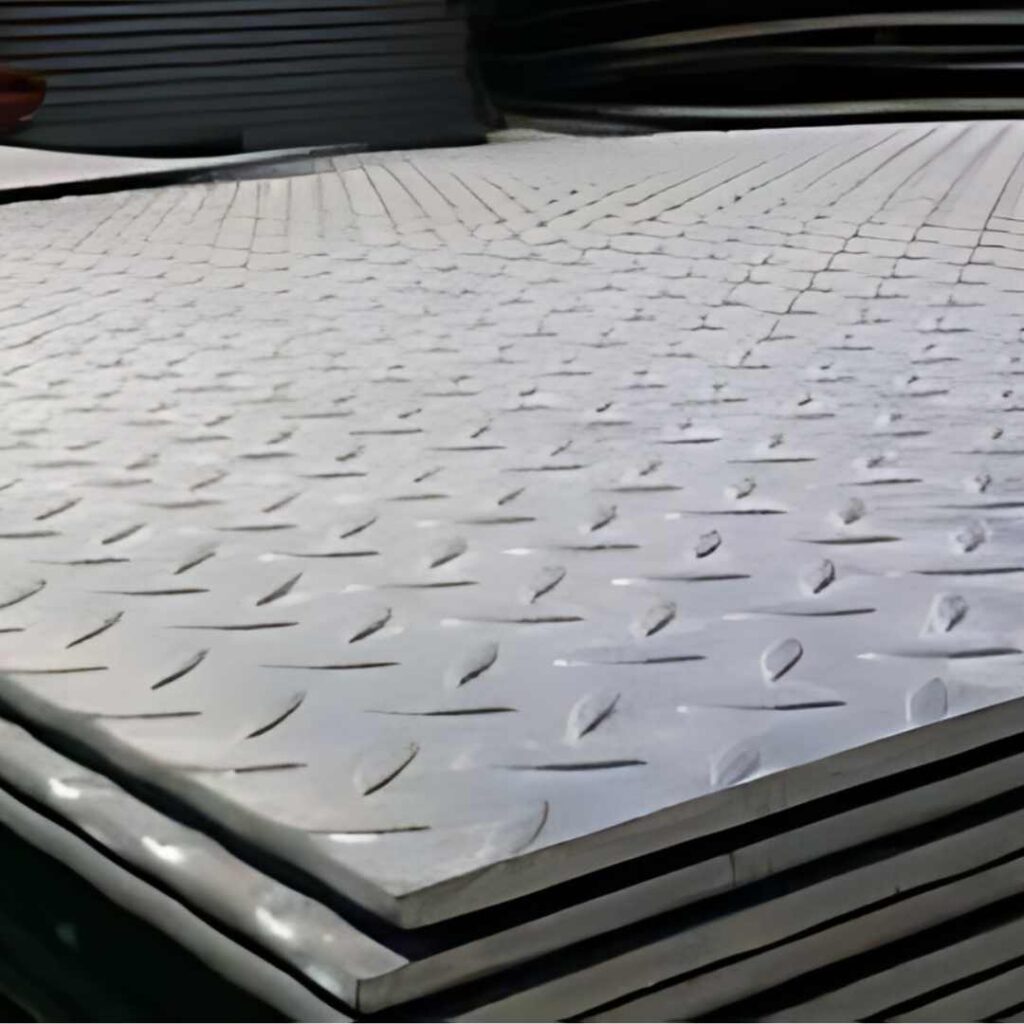

Chequered plates, often known as checker plates or diamond plates, are made from metal sheets that have a raised pattern on one side. They are commonly used in various applications due to their slip-resistant properties and durability. Here are some key points about chequered plates:

Tremie Pipes are specialized pipes used in construction and civil engineering, primarily for underwater concrete placement. Here’s a detailed overview:

Underwater Concrete Placement: Tremie pipes allow concrete to be poured underwater without the risk of it mixing with water, which can weaken the structure.

A tremie hopper is a device used in construction and civil engineering, particularly for underwater concrete placement.

Concrete Placement: The primary function of a tremie hopper is to facilitate the pouring of concrete in underwater conditions, preventing it from mixing with water and maintaining its integrity.

A tremie socket set is a specialized tool kit designed for use in underwater concrete construction. It typically includes various sizes of sockets and extensions that allow for the precise placement of concrete in deep or submerged applications. Here are some key points about a tremie socket set:

PO Box 16122, Collins Street West,

Victoria 8007 Australia

SUPPORT: 1800 425 4646

OFFICE: +1 (253) 2587 220

SUPPORT: 1800 425 4646

OFFICE: +1 (253) 2587 220

Collaboratively deliver partnerships progressive alignments. Assertively premier supply chains before emerging solutions. Monetize high-payoff action items before wireless internal or “organic” sources exceptional action items.